Hot-dip galvanizing is the most effective and reliable method for protecting metals against corrosion

Hot-dip galvanizing is the most effective and reliable method for protecting metals against corrosion. It combines the availability of technology and minimal operating costs with high protective properties, providing the protection of metal structures for the maximum duration. The zinc layer, which is formed by immersing the product into melted liquid zinc at a temperature of 450 degrees, melts onto the steel surface from all sides and forms a durable, sustainable and impermeable coating that provides not only a physical barrier against corrosion, but also electrochemical protection.

Depending on the brand of steel, the zinc coating may look smooth and bright, or grey and matte. In any case, the change in its appearance does not affect the properties of the coating in any way.

Advantages

In addition to its unique corrosion resistance, hot-dip galvanizing technology has a number of other significant advantages as well. This method allows one to treat even the most complex of details, including products of non-standard geometric shape.

Zinc protects steel from rusting, if, for example, minor damage and/or scratches occur. This type of damage is filled with zinc oxides and carbonates, which slow down further corrosion.

Area of use

Galvanized steel structures are used in various areas of construction. They are irreplaceable in the construction of bridges, telecommunications towers, engineering, industrial and public buildings, as well as in the agriculture and energy industry. Hot-dip galvanizing is especially appreciated in objects that are located in an aggressive, corrosion-enhancing environment.

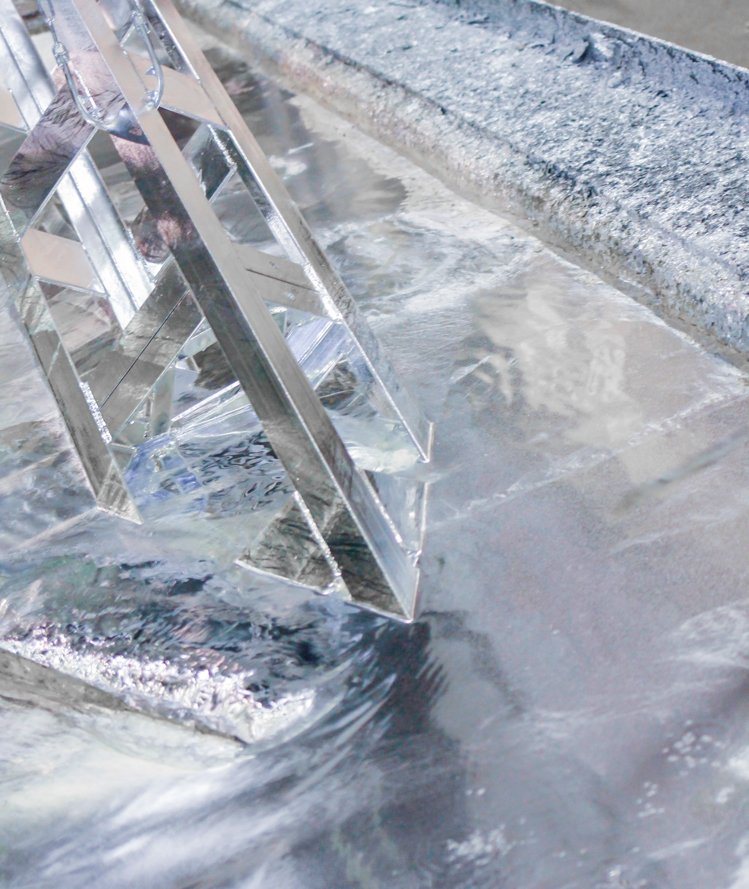

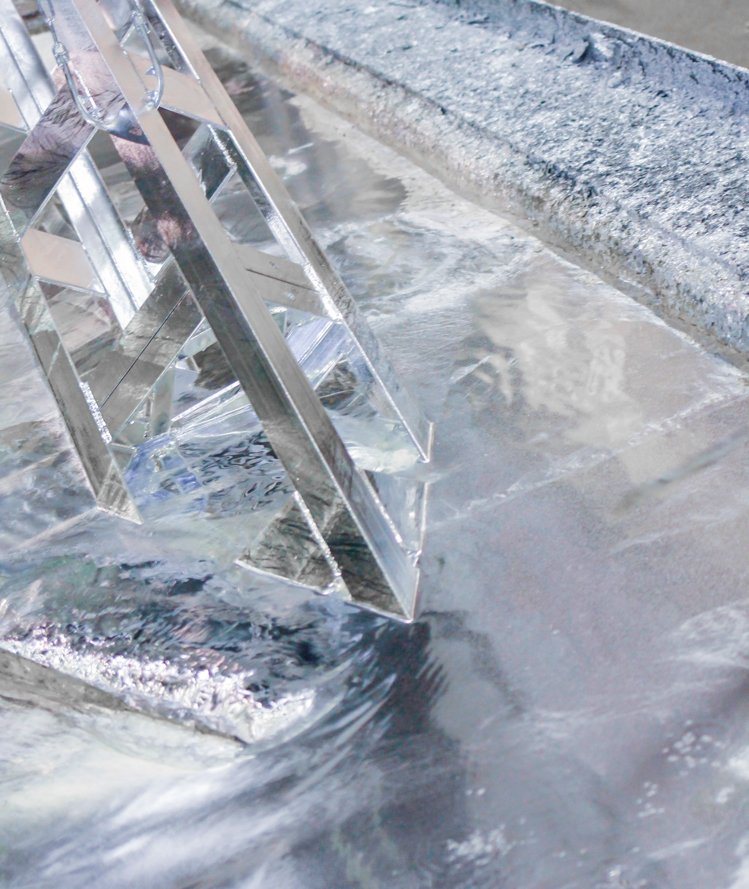

Today, hot-dip galvanizing is no longer used for anti-corrosion protection only.

Over time, the zinc coating forms beautiful geometric and floral shapes on steel, which makes it possible to use structures as a complement to the design.

Hot-dip galvanizing is the most effective and reliable method for protecting metals against corrosion

Hot-dip galvanizing is the most effective and reliable method for protecting metals against corrosion. It combines the availability of technology and minimal operating costs with high protective properties, providing the protection of metal structures for the maximum duration. The zinc layer, which is formed by immersing the product into melted liquid zinc at a temperature of 450 degrees, melts onto the steel surface from all sides and forms a durable, sustainable and impermeable coating that provides not only a physical barrier against corrosion, but also electrochemical protection.

Depending on the brand of steel, the zinc coating may look smooth and bright, or grey and matte. In any case, the change in its appearance does not affect the properties of the coating in any way.

Area of use

Galvanised steel structures are used in various areas of construction. They are irreplaceable in the construction of bridges, telecommunications towers, engineering, industrial and public buildings, as well as in the agriculture and energy industry. Hot-dip galvanizing is especially appreciated in objects that are located in an aggressive, corrosion-enhancing environment.

Today, hot-dip galvanizing is no longer used for anti-corrosion protection only.

Over time, the zinc coating forms beautiful geometric and floral shapes on steel, which makes it possible to use structures as a complement to the design.

Advantages

In addition to its unique corrosion resistance, hot-dip galvanizing technology has a number of other significant advantages as well. This method allows one to treat even the most complex of details, including products of non-standard geometric shape.

Zinc protects steel from rusting, if, for example, minor damage and/or scratches occur. This type of damage is filled with zinc oxides and carbonates, which slow down further corrosion.

We offer all surface treatment processes from shot blasting to galvanizing and painting, as well as we guarantee process control and quality at each stage of the treatment and ensure that the final product is of the required quality.

Contact Us