More posts

Read more

Read more

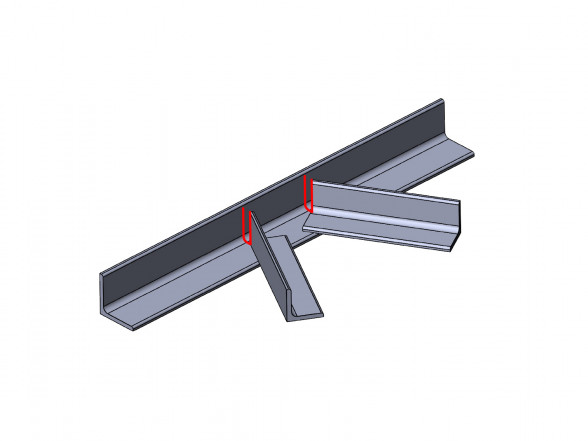

Stiffeners and gusset plates

Always design stiffeners and gusset plates so that zinc cannot be trapped in corners.

Read more

Read more

We are grateful and happy to share our success with Bērnu Klīniskā Universitātes Slimnīca

Read more

">It would not be possible without our great employees and partners support. Together we can achieve more and become better to help each other.

Read more