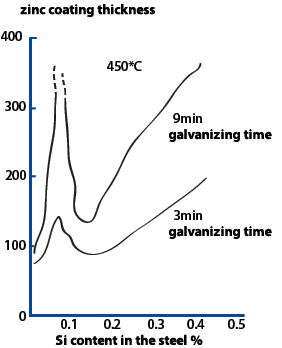

Thickness of zinc coating formed in the process of hot-dip galvanizing depends on the thickness of the structures, immersion time in the zinc bath, silicon contents in the steel as well as relationship of silicon and phosphorus in the steel.

For ordinary quality carbon structure steels the content of silicon (Si) should be within the limits of 0 – 0.04% or 0.15 – 0.25%

If silicon content in steel is 0.05 – 0.12%, zinc coating may become too thick and start cracking during usage.

The same regulations refer also to qualitative carbon steels. Carbon content up to 0.3% does not influence galvanizing process yet exceeding this concentration, too thick layer of zinc can form on the surface of steel. In addition, if the surface is too thick a layer of zinc.

When galvanizing alloyed structure steels, it should be observed that presence of aluminium in the steel gives the worst influence on hot-dip galvanizing process out of all the alloying elements. Thus its contents may not exceed 0.02%.

Automatic steel is most often not suitable for galvanizing due to too high sulfur content (more than 0.18%).

Hot dip galvanizing is not recommended for high-strength steels (over 1000 N / mm²), as steels can become brittle as a result of processing.

When requiring silicon guarantee for steel, buyer ensures also good adhesion of zinc coating. Good adhesion of zinc coating may be ensured also if buyer informs manufacturer of steel that it will be galvanized.

Relationship between the silicon content in steel and thickness of zinc coating