A few basic rules that should be followed when designing products for subsequent galvanizing.

Open as PDF

Basics

-

Follow designer’s instructions with regard to holes drilled in hollow structures.

-

Ensure additional clearance of approximately 1.5 mm on each side.

-

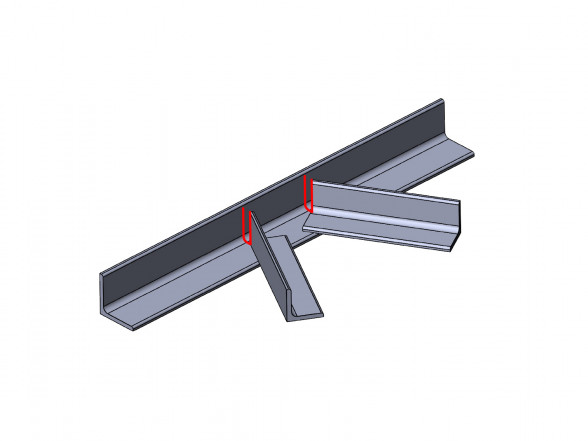

Avoid, if possible, overlapping surfaces. If that is impossible, follow strictly rules on drillings.

-

Remember that galvanizer has to lift and turn your articles. Make sure that you have ensured possibility to lift your article.

-

Avoid combining materials of different thickness that can cause deformation due to different cooling time.

-

Avoid big size thin metal sheets. Unless stiffened, they might warp.

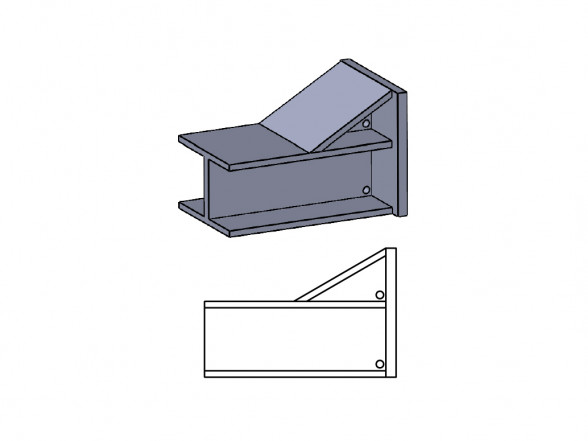

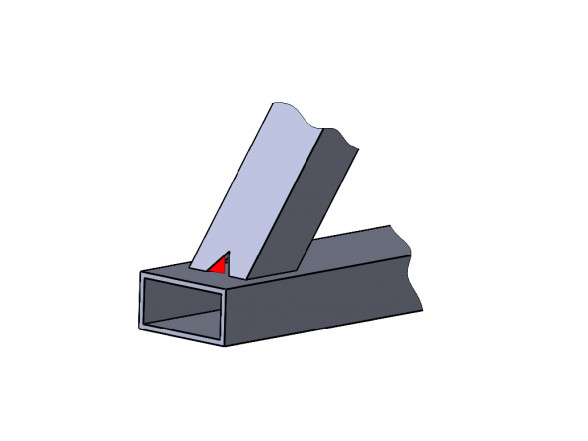

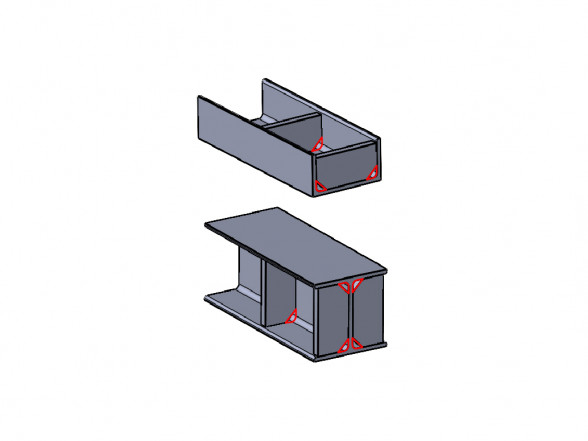

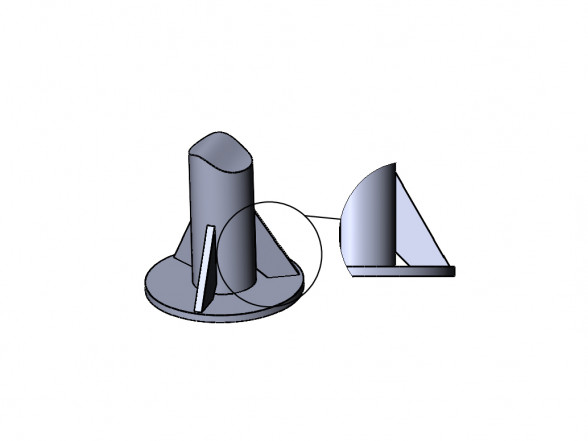

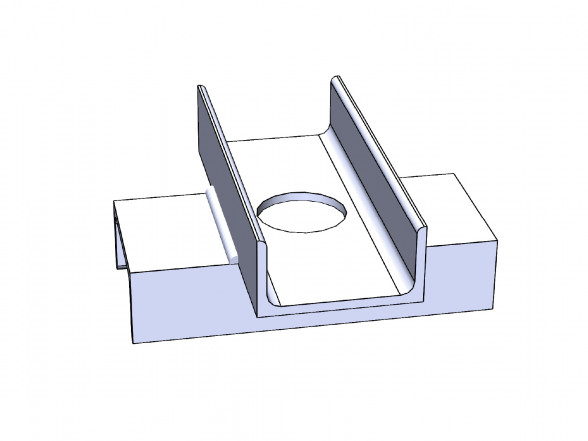

Designing Holes

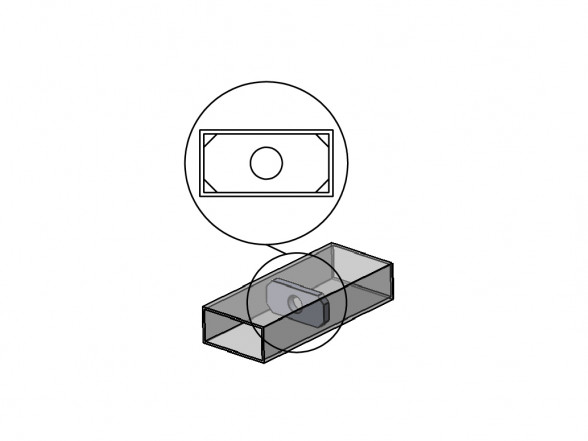

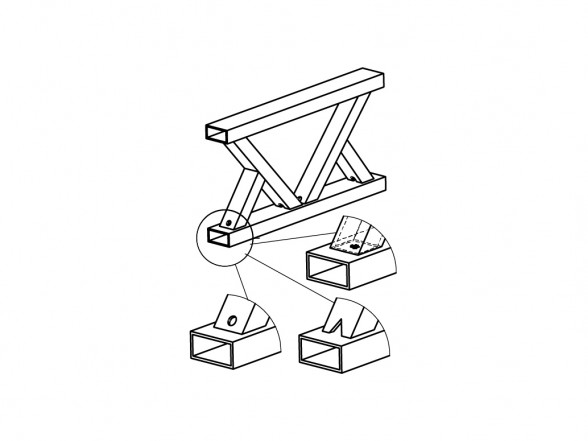

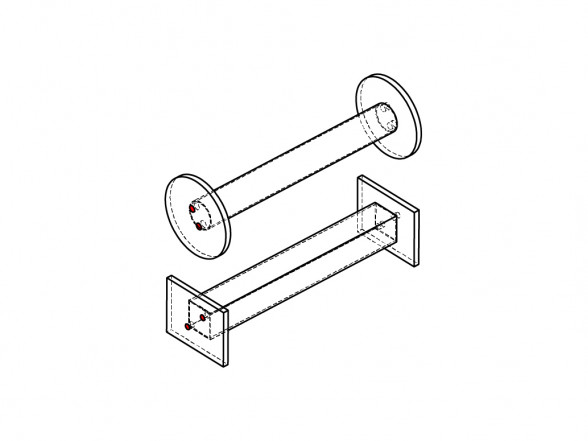

When designing hollow steel articles, proper size and dislocation holes should be provided for zinc drainage, as well as venting upon influx of zinc. In case that is not ensured, there is a risk of two things to happen. Firstly, structure may explode upon on immersion in zinc bath when internal moisture turns into vapour. Secondly, steel will not be covered with zinc from inside since it will not get inside. Galvanizer will drill holes instead of you but it is much more difficult to drill in a ready structure without auxiliary devices therefore the price of one such drill can be very high.

There is no need to cover these holes after galvanizing since airflow through hollow section ensures better conditions for life cycle of zinc coating. In case of necessity to close the holes, plastic or aluminium cone plugs should be used.

Recommended Size of Holes (mm)

| Length of the article | 0-2000 | 2000-4000 | 4000-6000 | 6000-8000 | 8000-10000 |

| Size of the pipe | |||||

| 0-25 | 8 | 10 | 12 | 12-14 | 14-16 |

| 25-50 | 8-12 | 10-12 | 12-16 | 20-30 | 25-30 |

| 50-100 | 12-20 | 12-30 | 15-30 | 30-50 | 30-50 |

| 100-200 | 20-40 | 30-50 | 30-50 | 50-80 | 50-90 |

| 200-300 | 40-80 | 50-100 | 50-100 | 100-120 | 100-130 |

| 300-400 | 80-100 | 100-120 | 100-120 | 120-150 | 100-160 |

| 400-500 | 100-150 | 120-200 | 120-200 | 200-250 | 200-300 |

| 500-600 | 150-200 | 200-250 | 200-300 | 300-350 | 300-350 |

These dimensions refer to all types of hollow beams, UNP and IPE beams, as well as welded hollow structures.